Laboratory Casting Plant based on semicontinuous casting unit for manufacturing of rolling ingots and extrusion billets

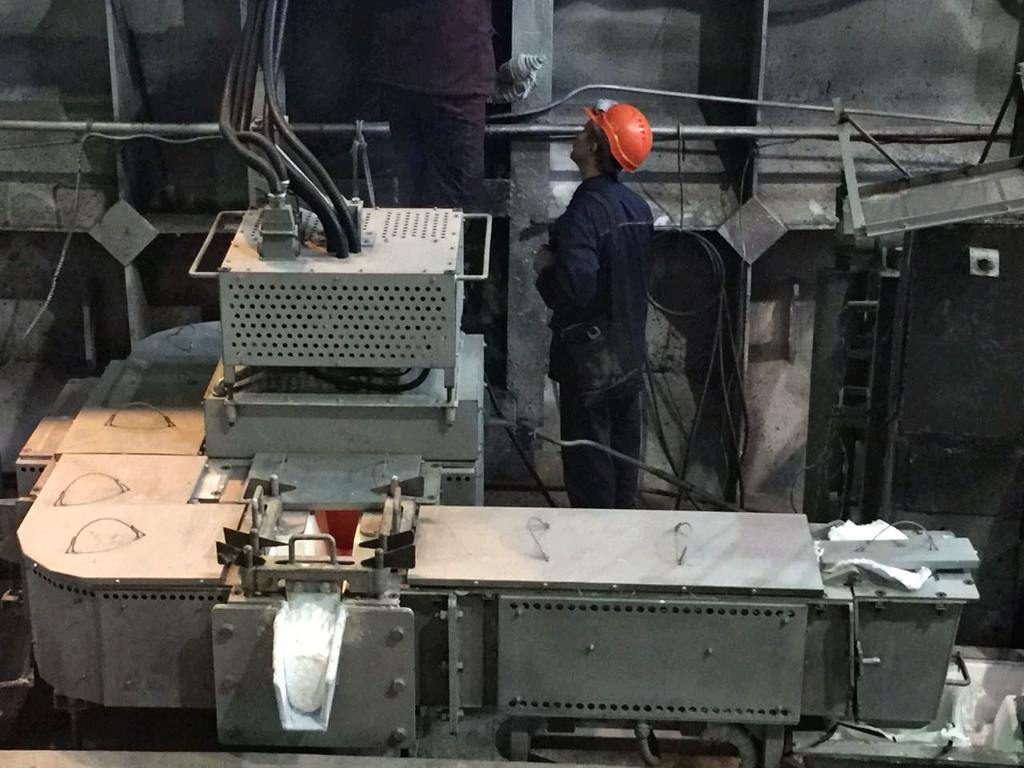

The unit was designed and manufactured for a laboratory based at the Siberian Federal University for the development of processes and technology of semi-continuous casting of rolling ingots and extrusion billets. Features of the unit are the ability to melt a solid charge and prepare melts of given chemical composition in a rotary resistance stirrer and simulation of real production conditions.

Task:

- Автоматизируемые процессы/системы: система подачи воды в кристаллизатор литейной машины, механизм подъема/опускания литейной платформы, а также системы нагрева и поворота наклонного миксера

- Manufacturing of a casting unit on the basis of the UPNL casting machine, two crucible rotary furnaces PPI-0.16 and a rotary resistance holder

- The work included automation of the processes in accordance with the documentation developed by our specialists

- Automated processes/systems: system of water supply to the mold of the casting machine, mechanism of casting platform raising/lowering, and heating and turning systems of the tilting holder

Customer:

FSAEI HE Siberian State University, Krasnoyarsk

Project Year:

2018

Problems prior to implementation:

- Crucible furnaces PPI-0,16 do not function

- Holder of small-capacity and insufficient functions

- Outdated casting platform control system

- Lack of automated water supply to the caisson

- Lack of a single working platform and launders

- Localized control systems without integration into the main PLC

Key features:

Resistance holder:

- Temperature of heaters 800-900°С

- Capacity of molten aluminum bath 100 kg.

- Maximum angle of holder rotation 29°С

- Separate control of the heating power of each of three zones of silicon carbide heaters

- Electromechanical lift drive

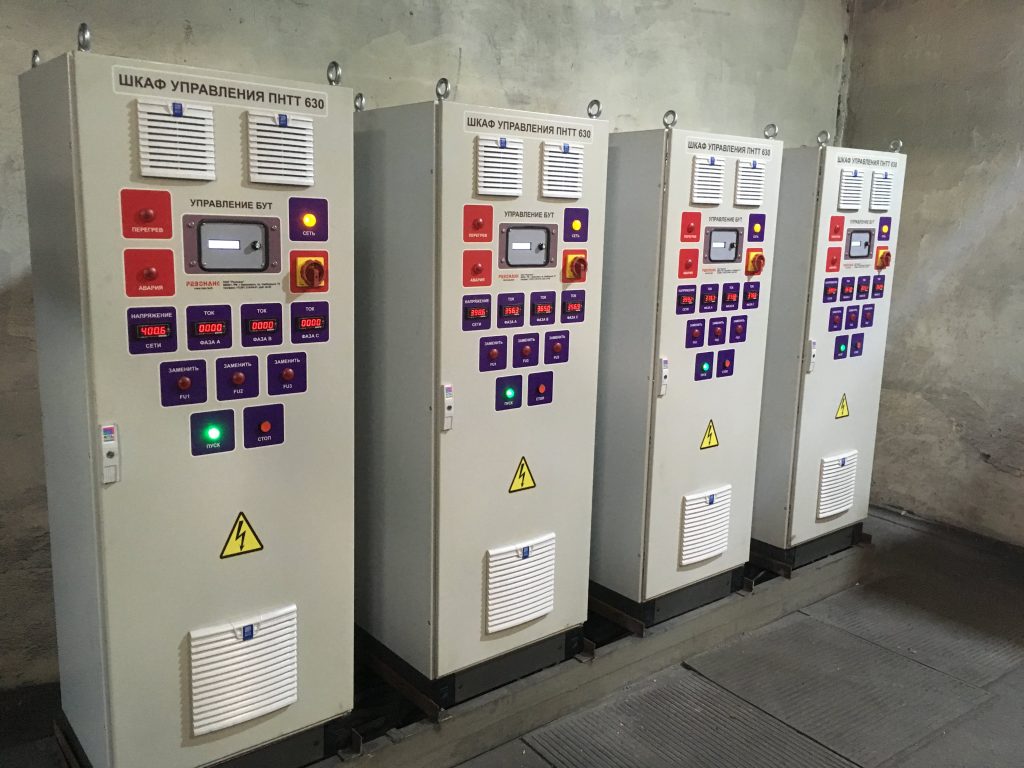

Control cabinet:

- Total power 31 kW

- PID controller

- Thyristor power control

- Cabinet 1200х600х300 mm

- Degree of protection – IP65

Launder:

- Refractory Concrete Cartridges

- 95 mm deep trays

- Four sliding valves

Jib crane:

- Load capacity 250 kg

- length of jib up to 3 m

- The manual rotary actuator of the jib

- Lifting speed – up to 8 m/min

Ventilation:

- Volume of vented gases up to 2700 m3/hour

- Material of the duct – galvanized steel

Result:

![]() Reduction of ingot crop ends to three times

Reduction of ingot crop ends to three times

![]() Heat losses of the melt during start-up decreased down to 0.5°C/m

Heat losses of the melt during start-up decreased down to 0.5°C/m

![]() Fast warming-up of concrete cartridges within 1.5–2 hours

Fast warming-up of concrete cartridges within 1.5–2 hours

![]() Flexible heating control

Flexible heating control

![]() Easy maintenance and good maintainability

Easy maintenance and good maintainability