Two units of filtration of aluminum melt UFP 12M

17.07.2018

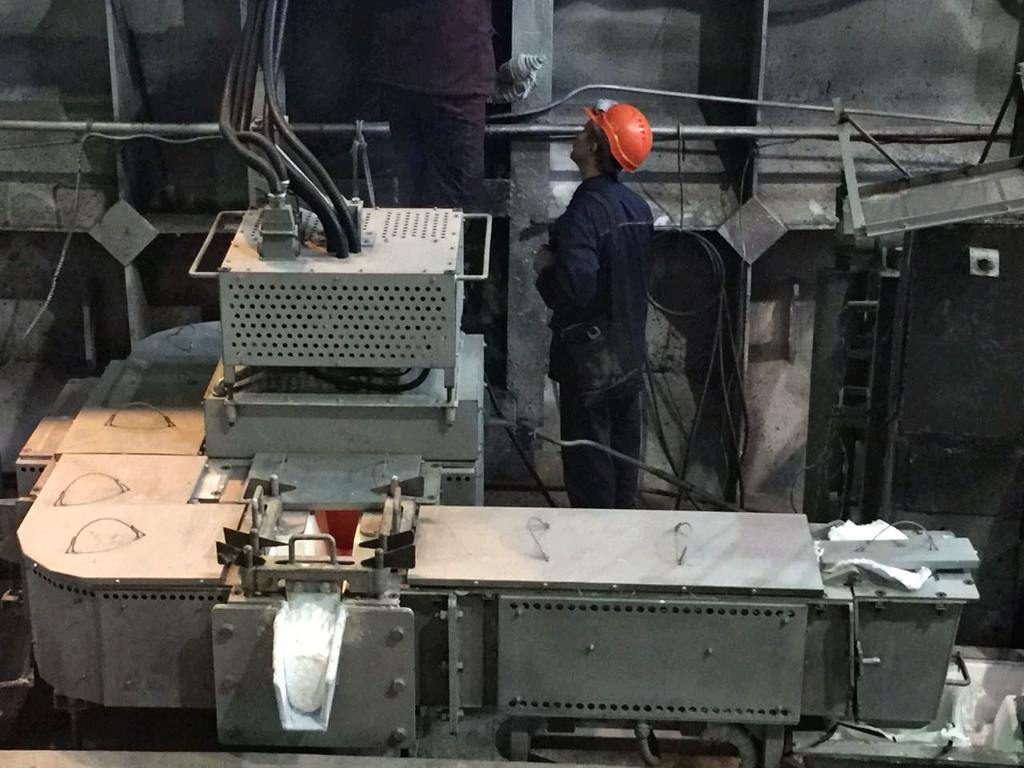

Open melt overflows

11.07.2018Task:

Filtration of aluminium melt from non-metallic inclusions through the ceramic foam insert in the line of aluminium ingot production

Customer:

RUSAL Krasnoyarsk JSC, Krasnoyarsk, Casthouse No.1, conveyors No.1 and No.2

Project Year:

2015

Issues prior to implementation:

- Complicated casting start-up with filter porosity more than PPI20

Key Features:

Power of the radiation heaters is 10 kW (900°С)

Power of the convection heater is 8 kW (550 °С)

Pneumatic lifting drive

SIEMENS automatic equipment

Result:

Warming-up of the filtration chamber cartridge up to 600°C and warming-up of the ceramic foam insert prior to casting

Warming-up of the filtration chamber cartridge up to 600°C and warming-up of the ceramic foam insert prior to casting

Possibility of quick start with filter porosity up to PPI50

Possibility of quick start with filter porosity up to PPI50

Change over to SiO2 based concrete

Change over to SiO2 based concrete

Improvement of production process automation

Improvement of production process automation