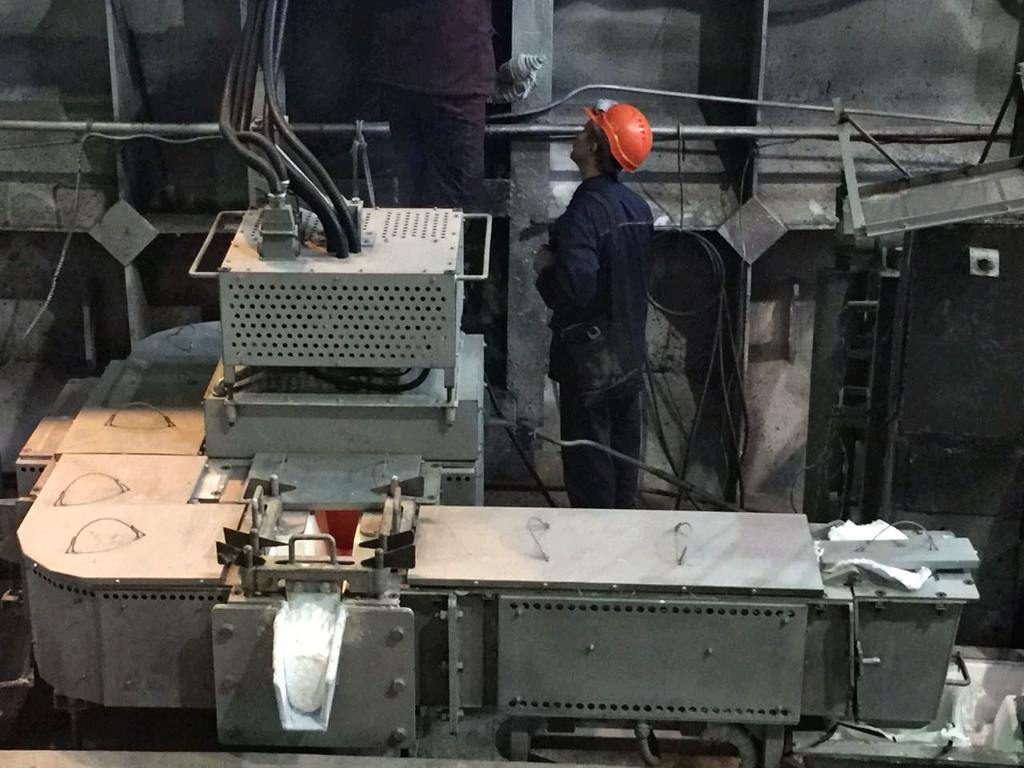

Two twin units of filtration of aluminum melt UFP 15

18.07.2018

Two units of filtration of aluminium melt

12.07.2018Task:

Filtration of aluminium melt from non-metallic inclusions through the ceramic foam insert in the line of aluminium ingot production

Customer:

RUSAL Krasnoyarsk JSC, Krasnoyarsk, Casthouse No.1, conveyors No.3 and 4

Project Year:

2014

Issues prior to implementation:

- Complicated casting start-up with filter porosity more than PPI20

Key Features:

Power of the radiation heaters is 10 kW (900°С)

Power of the convection heater is 8 kW (550 °С)

Pneumatic lifting drive

SIEMENS and EKF automatic equipment

Result:

![]() Warming-up of the filtration chamber cartridge up to 600°C and warming-up of the ceramic foam insert prior to casting

Warming-up of the filtration chamber cartridge up to 600°C and warming-up of the ceramic foam insert prior to casting

![]() Possibility of quick start with filter porosity up to PPI20

Possibility of quick start with filter porosity up to PPI20

![]() Change over to SiO2 based concrete

Change over to SiO2 based concrete

![]() Improvement of production process automation

Improvement of production process automation