The project is an integrated turnkey solution for transfer, filtration and casting of rolling ingots. The technical solutions are based on the most effective and proven achievements of the company in the field of electric heating.

Task:

Automation of the mold tray installation/removal, melt transfer from the stirrer to the casting machine with minimal heat loss, and filtration from non-metallic inclusions.

Customer:

JSC RUSAL Krasnoyarsk, Casthouse 2

Project Year:

2018

Problems prior to implementation:

- application of asbothermosilicate plates and ceramic cardboard for lining

- bad start-up of casting through a ceramic foam filter

- great content of titanium diborides due to the small length of a launder

- non-automated heating and metal distribution processes

Key Features:

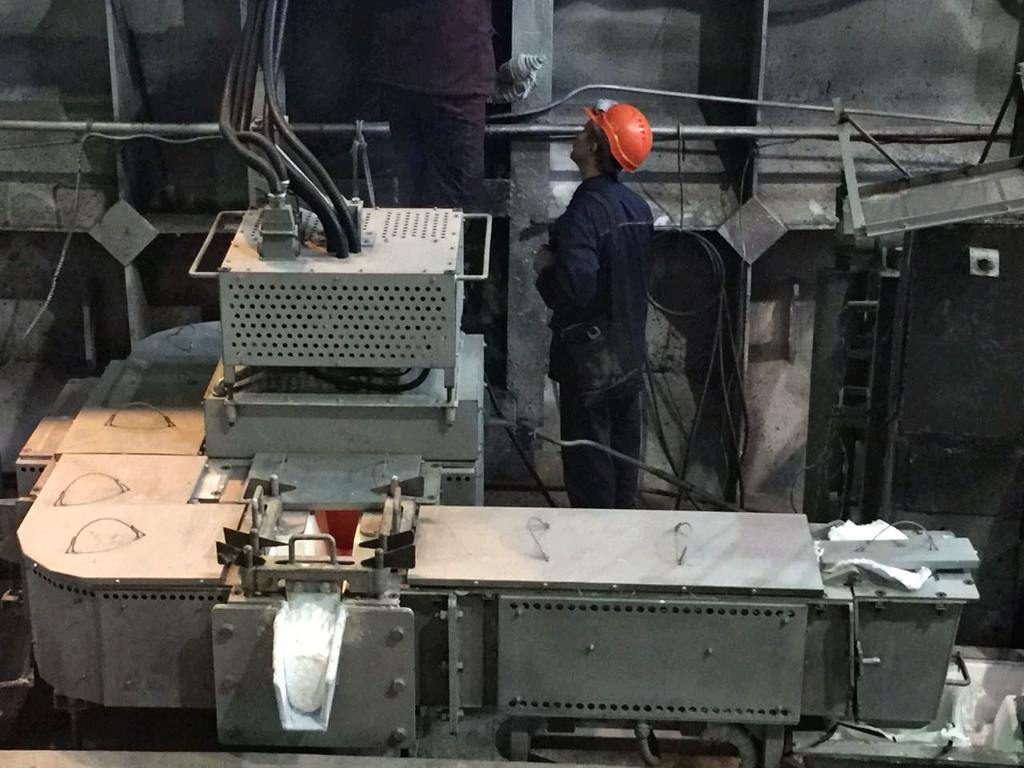

- Mold tray on a sliding electromechanical platform

An automated electromechanical sliding platform for two types of mold trays – for 2 and 4 ingots

Mold tray pre-heating system – 4 arch cover 10 kW each

Possible pre-heating of dosing sleeves

Mold tray hydraulic lifting system integrated into the casting table

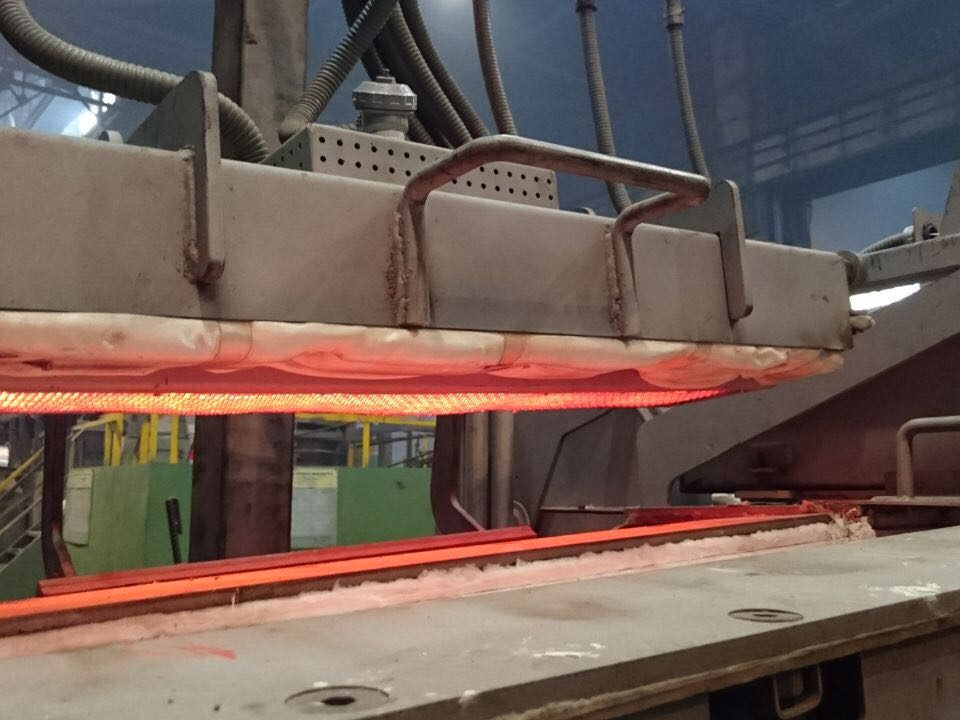

- 20″ filtering box with combined heating system

Filtering box ceramic foam filter 20″ with combined heating system -convective system power is 30 kW

infrared system power is 25 kW

Warming-up time of a foam ceramic filter up to 650°C – 40 minutes

Protection of heaters against splashes of melt, protection against overheating and lack of air

Electromechanical drive for the lifting of the filtering box cover

- Launder with electric heating system

The heating system of fixed launder – 6 arch covers 10 kW each

Length of launder – 11 m

The range of consumption – 8 -21 t/h

Pneumatic slide valves with manual control – 3 pcs

- Control system

SIEMENS PLC control system

Thyristor control based on noise-immune thyristor control units BUT-3U

Result:

![]() The process of the mold tray installation and removal from the casting machine is automated

The process of the mold tray installation and removal from the casting machine is automated

![]() The mold tray heating system is installed on a sliding platform and allows to warm-up not only cartridges, valves and sleeves

The mold tray heating system is installed on a sliding platform and allows to warm-up not only cartridges, valves and sleeves

![]() Start-up of casting through the CFF is performed quickly and without the participation of a founder

Start-up of casting through the CFF is performed quickly and without the participation of a founder

![]() The level of heat loss during casting is not more than 1 s/m

The level of heat loss during casting is not more than 1 s/m

![]() Titanium diboride level is reduced to a minimum required level

Titanium diboride level is reduced to a minimum required level

![]() Expanded opportunities for the production of new types of ingots

Expanded opportunities for the production of new types of ingots

Similar Projects

Two units of filtration of aluminium melt UFP 12

2017, JSC RUSAL Novokuznetsk, Casthouse 1- Client

- 2017, JSC RUSAL Novokuznetsk, Casthouse 1

Electrically Heated Tray

2017, KraMZ LLC, melting and casting unit 2- Client

- 2017, KraMZ LLC, melting and casting unit 2

15 inch aluminium melt filtration unit

2017, KraMZ LLC, melting and casting unit 3- Client

- 2017, KraMZ LLC, melting and casting unit 3

Filtering box and launder heating system

2016, KraMZ, Melting and casting unit №1- Client

- 2016, KraMZ, Melting and casting unit №1

The launder with sliding mold tray and filtering box

2018, JSC RUSAL Krasnoyarsk, Casthouse 2- Client

- 2018, JSC RUSAL Krasnoyarsk, Casthouse 2

Two twin units of filtration of aluminum melt UFP 15

2015, RUSAL Bratsk, Shelehov- Client

- 2015, RUSAL Bratsk, Shelehov