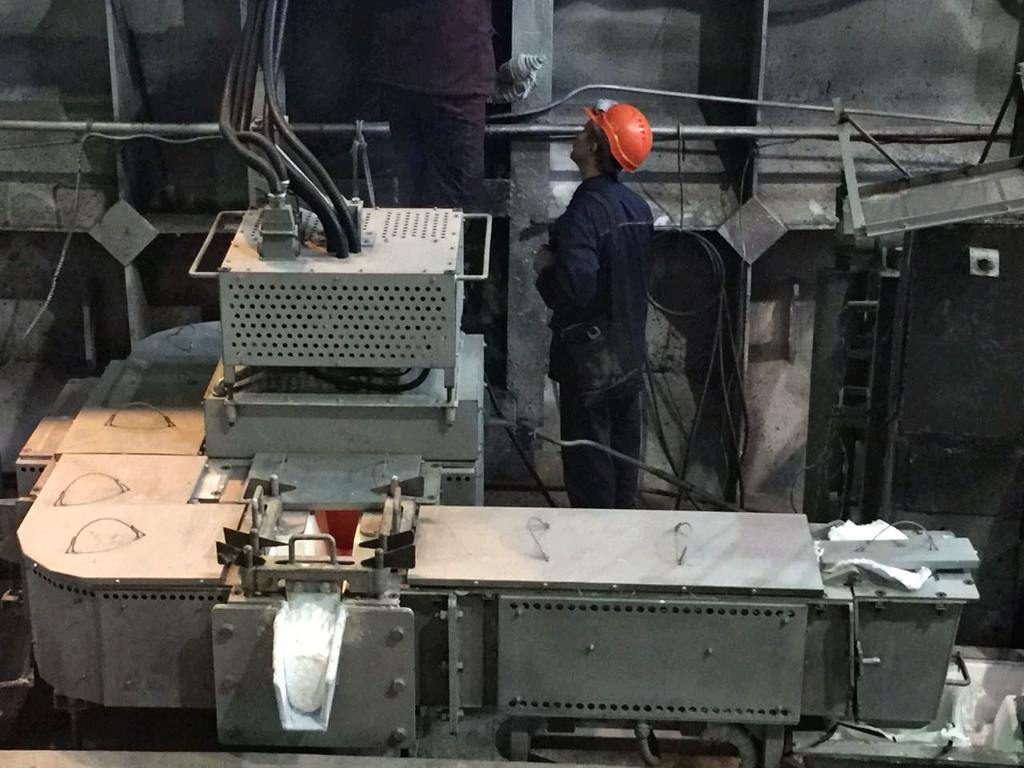

Laboratory Casting Plant

31.05.2019

Welding transformer for the anode busbar

28.07.2018The unit was developed with consideration of peculiarities of the Wagstaff casting machine. It is based on 2 power-driven covers with convection heaters blowing of which is performed with the designated system developed by our company and based on the operation of the air blowing/vacuuming tool with cyclone dust cleaning. Application of the unit, along with convenient operation and even heating, allowed to avoid entering of floating crystals into products.

Task:

Warming-up of the mold tray with hot air prior to casting on the large-sized flat-shaped ingots casting lines

Customer:

RUSAL Krasnoyarsk JSC, Casthouse No. 3, Casting Unit No. 5

Project year:

2016

Problems prior to implementation:

- Application of unreliable portable infra-red heaters

- Human factor during the use of heaters

Key features:

- Two covers with convection heaters — 16 kW each (550°C)

- Two-level air cleaning system

- Vacuum air blowing/vacuuming tool for compressed air blasting

- Stationary design with the mechanism of manual lifting

- SIEMENS and ОВЕН automatic equipment

Result:

- Warming-up of the launder cartridge up to 450-500°C

- Mechanical protection of the heater

- Better conditions of the start-up in the winter time

- Easy and convenient maintenance