Welding transformer for the anode busbar

28.07.2018

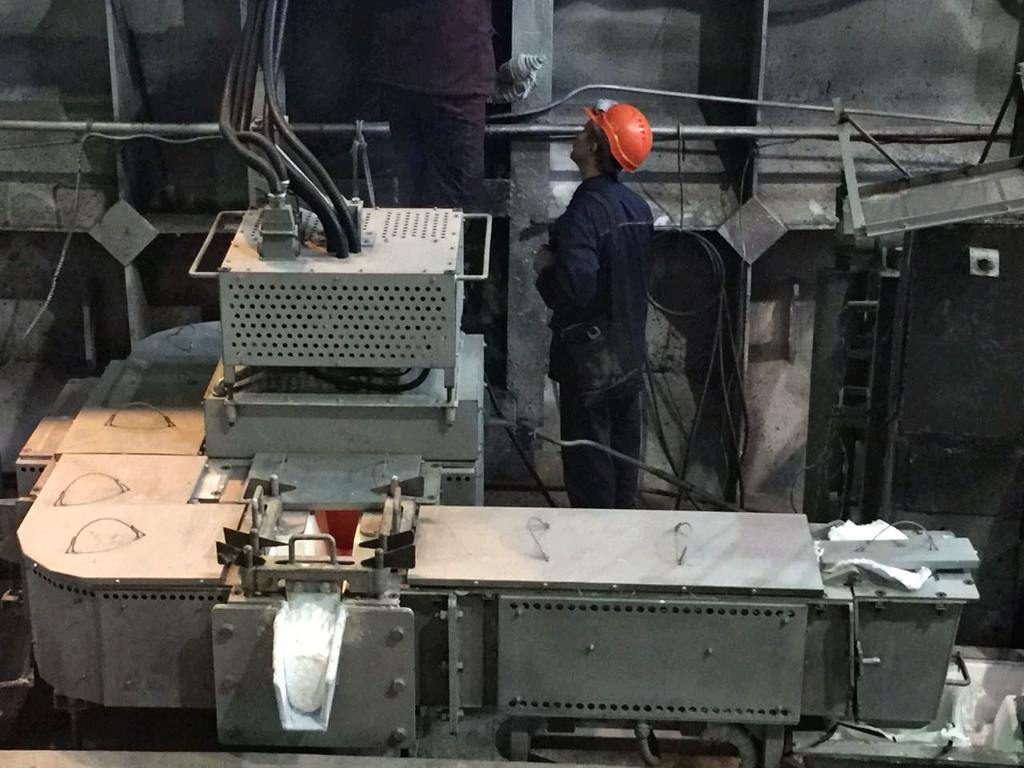

15 inch aluminium melt filtration unit

23.07.2018The baseline of the design is a heating system of the tray refractory cartridge by electric heaters of a unique design built in the lining, developed by our company. Heaters are installed along the side walls of the cartridge, which provides quick and uniform heating prior to casting up to temperatures of 600-650°C. Each heater is independently controlled and can be replaced without re-lining of the tray Special protection is installed to prevent melt leakage.

Task:

Warming up of a refractory cartridge prior to casting and compensation of the melt heat loss during casting on the aluminium wire line

Customer:

Krasnoyarsk Metallurgical Plant LLC, Krasnoyarsk, melting and casting unit No.2

Project Year:

2017

Problems Prior to Implementation:

- Big melt heat loss during the start of casting

- The inability to install fixed lining heating equipment

Key Features:

- Radiation heater power – 6 kW (650°С)

- Working voltage 32V

- Heating power PID-regulator

- SIEMENS and OWEN automatic equipment

Result:

![]() Warming up of launder cartridge up to 650С

Warming up of launder cartridge up to 650С

![]() Melt leakage protection

Melt leakage protection

![]() Reduction in heat losses during start-up to 1,5-2°С

Reduction in heat losses during start-up to 1,5-2°С

![]() Modular replacement of heating elements

Modular replacement of heating elements