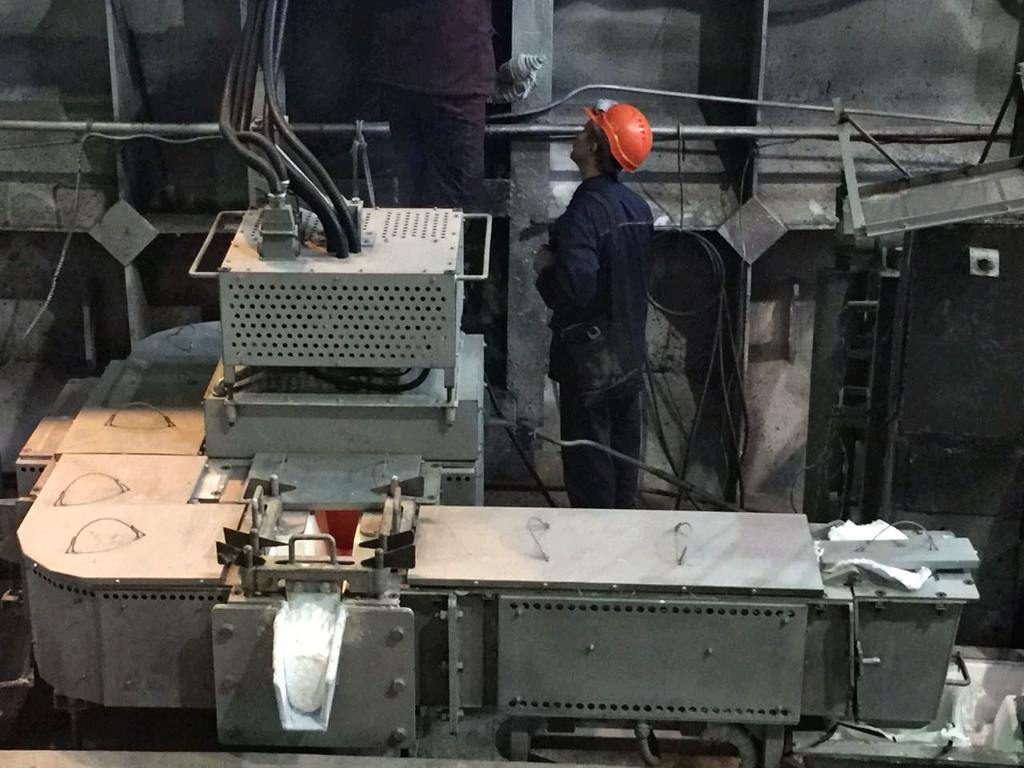

Transfer of melt

We manufacture launders according to individual customer requirements, taking into account the special conditions of equipment layout and operation

Benefits of heated launders:

Benefits of heated launders:

- Quick start of casting

- The reduction of the melt temperature in the furnace and the specific energy

- consumption per ton of finished product

- Reduction of the length of the cast bottom and quick obtaining the required casting temperature

- Partial or full compensation of heat loss prior to and during casting

Advantages of our products:

Advantages of our products:

- Convenience and safety of the operating personnel during the use of covers and launders

- Minimization of heat losses due to optimum tray sections

- Possibility of heating the melt in the launders during casting

- Special design for operation in rough conditions: at high dust conditions, polluted air and low quality of electrical power

- Unification of the automated control system: PLC and HIM based or without the use of PLC

Structural design

Possible design of launders

– Without heating system

– With radiation heating system based on arc heaters (arc-shaped heating elements with flexible ceramic mats)

– With convection heating system based on hot air guns (air blowing/vacuuming tool is used for blowing)

– With heating system with lining built heaters (flexible ceramic mats are used as heaters, protection from melt leakage)