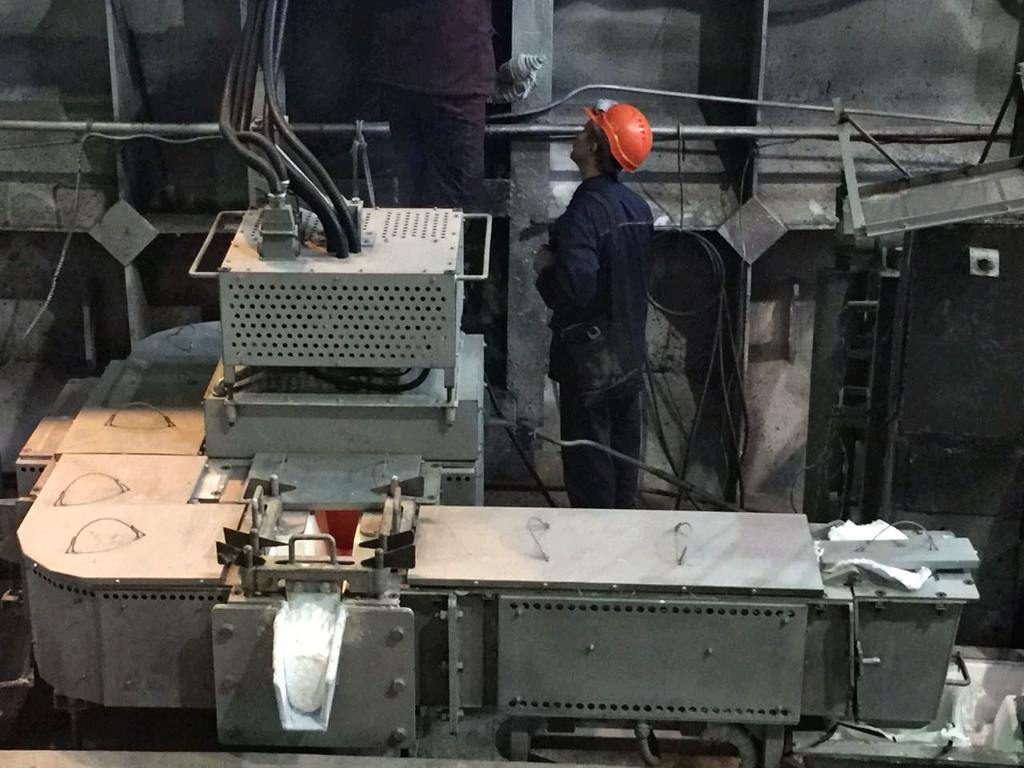

Filtration of melt

Our company designs, manufactures and supplies filtration units with different types of heating system.

Benefits of filtration units:

Benefits of filtration units:

- Quick start of casting and maximum use of effective surface of the ceramic foam filter due to its convection preheating with hot air

- High speed of cartridge and ceramic foam filter warming-up

- Maximum use of the effective surface of the ceramic foam filter due to convective preheating with hot air or combustion products

- Possible application of phosphate-free ceramic foam filters

- Preheating of melt during casting in filtering boxes with electrical heating system

Advantages of our products:

Advantages of our products:

Possible uniform heating of two-stage filters to a temperature of 650-700⁰C

Quick warming-up. gas filters: single-stage 20 min., two-stage 30 min. single-stage electric filters 60 min.

The flexibility of technological modes settings for solving specialized customer’s tasks using several methods of heat transfer in combined heating systems

Convenience and safety of the operating personnel during the use of filter covers

Special design for operation in rough conditions: at high dust conditions, polluted air and low quality of electrical power

Unification of the automated control system: PLC and HIM based

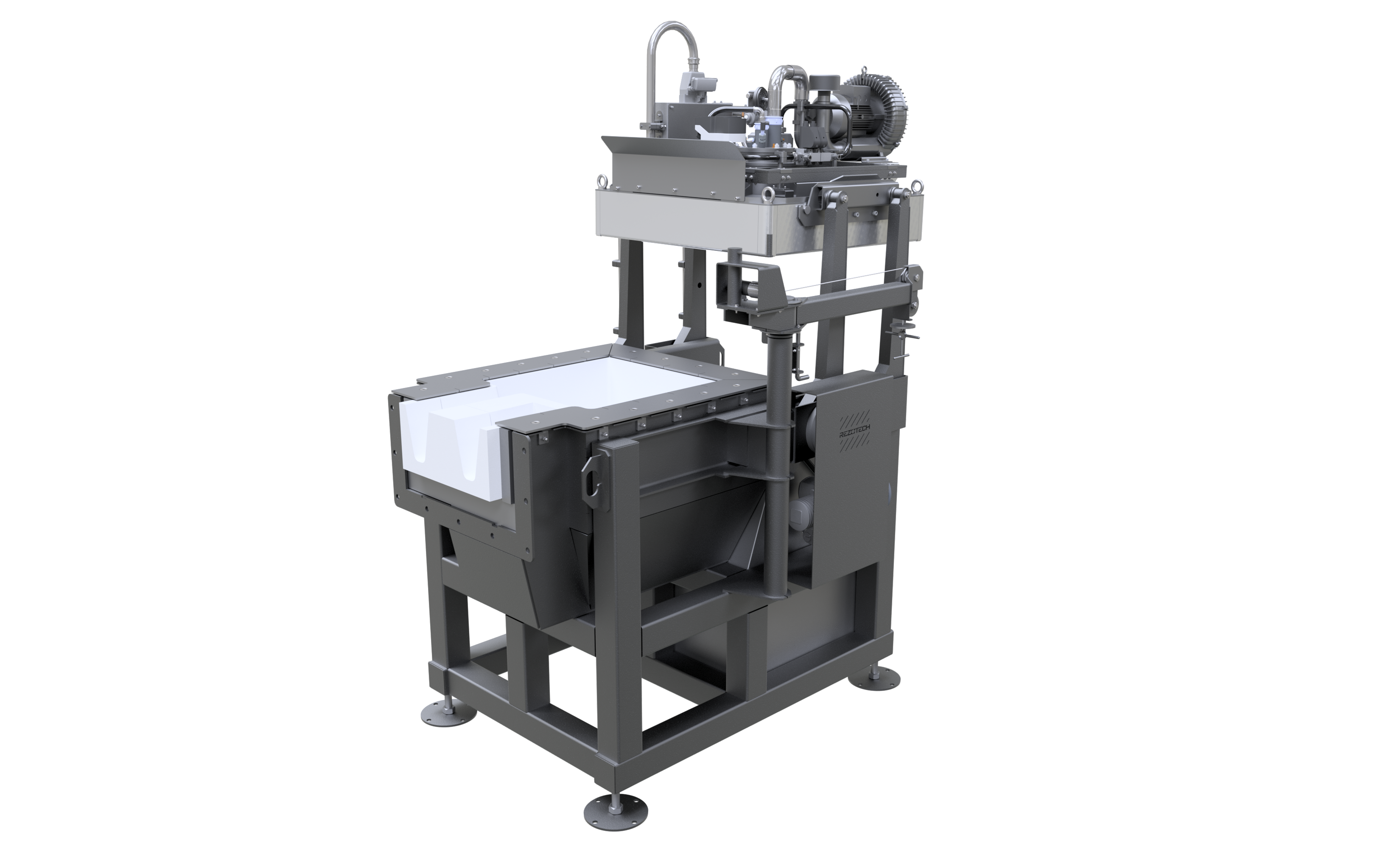

Structural Design

Possible design of filter box chambers for 10-23″ filters:

- Straight-through

- Twin

- By-pass

- Double filtration

Heating system options:

- Without a heating system

- With radiation heating system (filter box cover radiating surface always faces down)

- With convection heating system (air blowing/vacuuming tool and hot air gun are used for blowing)

- With combined heating system (radiation and convection heating)