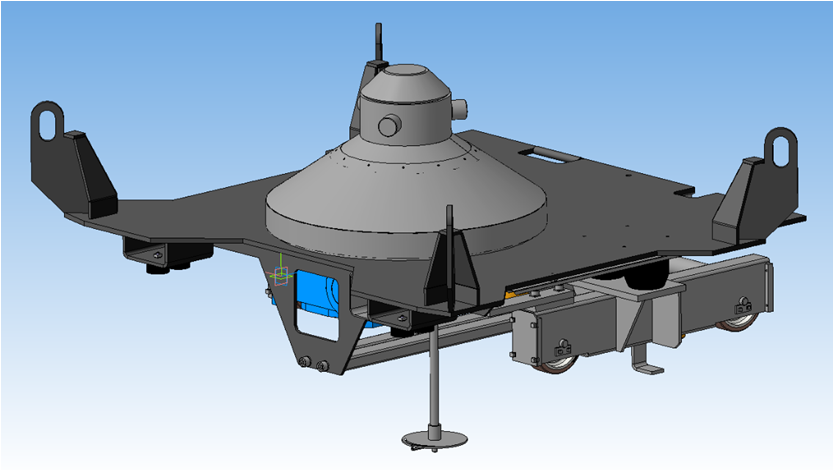

CASTING MACHINE OVERHAUL PROJECT

25.07.2018

Project for installation of nonmagnetic plate of the electromagnetic stirrer

13.07.2018Task:

Upgrade of the system of lubrication feed to the molds of the casting machine in order to warp-up the oil tank and the pipe system in winter

Customer:

RUS-Engineering LLC for “RUSAL Krasnoyarsk” JSC, Casthouse No.3

Project Year:

2017

Issues prior to implementation:

- Oil tank of small capacity without heating system

- Heating of pipes only before the casting table

- No oil level and temperature indication in the operator’s room

Key Features:

Metal structures, power equipment and automatic manufacturing process drawings

Result:

![]() Capacity of the oil tank is increased up to 40 liters

Capacity of the oil tank is increased up to 40 liters

![]() Heating, temperature and oil level control system

Heating, temperature and oil level control system

![]() Heating of pipes before molds with self-regulating heating cable

Heating of pipes before molds with self-regulating heating cable

![]() The control panel with indication of control parameters

The control panel with indication of control parameters