ELECTROMAGNETIC STIRRING OF MELT

Electromagnetic stirring – is a technology of noncontacting exposure of variable magnetic current to aluminum melt in furnaces and mixers in order to stimulate melting processes of a bulk charge and fast equalizing of a chemical composition during alloying process.

EFFECT ACHIEVED BY ELECTROMAGNETIC STIRRING:

EFFECT ACHIEVED BY ELECTROMAGNETIC STIRRING:

- Increasing in furnace productivity up to 25%

- Fuel saving up to 15%

- Decreasing in slag-making up to 25%

- Equalizing of temperature and chemical composition up to 1-2%

- Automation of the melt preparation process

- Expansion of alloy range

The uniqueness of electromagnetic stirrers manufactured by our company:

The uniqueness of electromagnetic stirrers manufactured by our company:

- A power supply based on the overall industrial frequency convertor

- Application possibility for furnaces with a capacity of up to 5 tons

- An original inductor’s construction with optimal weight-size parameters

- Customized modes of stirring settings

- A reliable and highly effective system of inductor’s air cooling with dust extraction

Advantages:

Advantages:

- Air cooling of conductive parts with reliable dust extraction systems that are maintenance-free during the whole period of the device operation (7-10 years)

- A short pay-back period for furnaces with a capacity of up to 5 tons

- One portable stirrer can supply 2 or more furnaces/mixers

- Low operating costs

Types Of Equipment

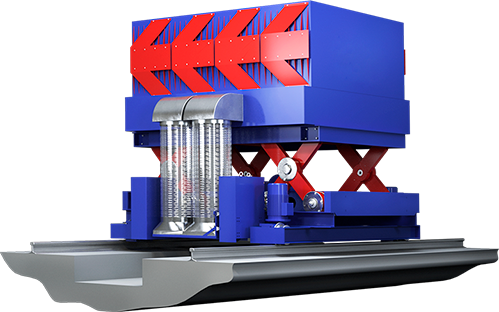

BOTTOM-MOUNTED ELECTROMAGNETIC STIRRER

APPLICATION:

- Tilting mixers or furnaces with no lift table (an inductor is moved to the working area when a mixer/furnace is in an elevated position)

- Fixed mixers/furnaces with a lift table

- Tilting mixers/furnaces with a lift table

- Several fixed or tilting mixers/furnaces with a movable inductor located on a lift table

SIDE-MOUNTED ELECTROMAGNETIC STIRRER

APPLICATION:

- In cases when construction does not allow to install more effective electromagnetic stirrer in a horizontal position under the bottom of the furnace

- In cases when during the furnace operation a necessity of increasing its effectiveness or upgrading to new alloys with higher value-added arises

- In cases when a bath’s geometry or technology of an alloy preparation requires an installation of an electromagnetic stirrer on one of the sides of a furnace