Chemical Treatment

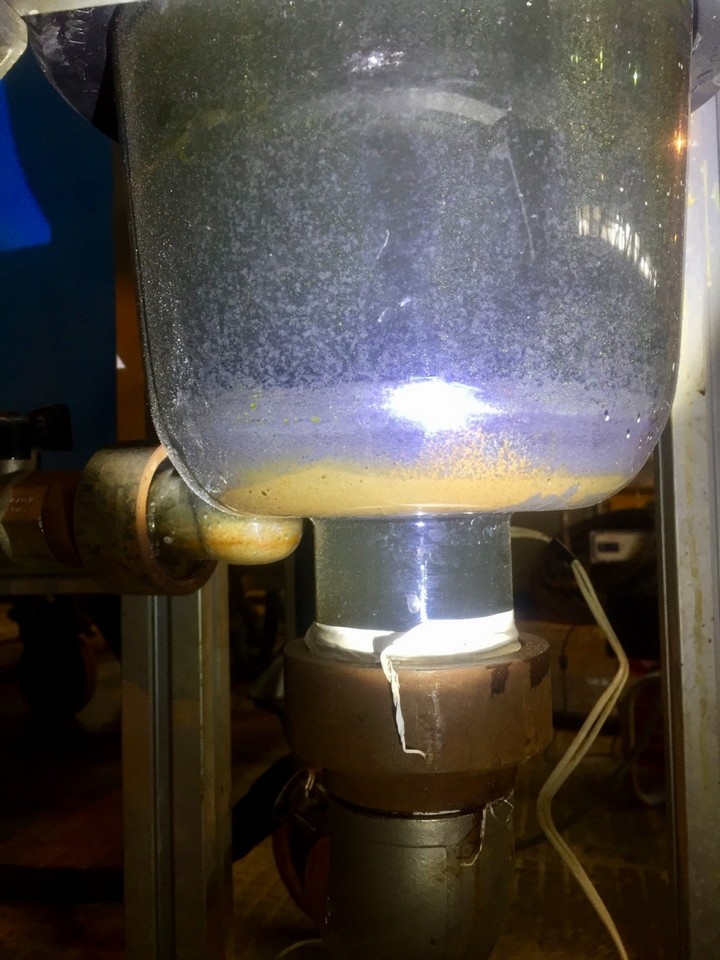

We offer a unique, environmentally friendly method for clean-in-place procedures for industrial equipment from simple and complex deposits of different nature.

Cleaning operations are performed using an automated independent system with calibration by type of deposits.

Application:

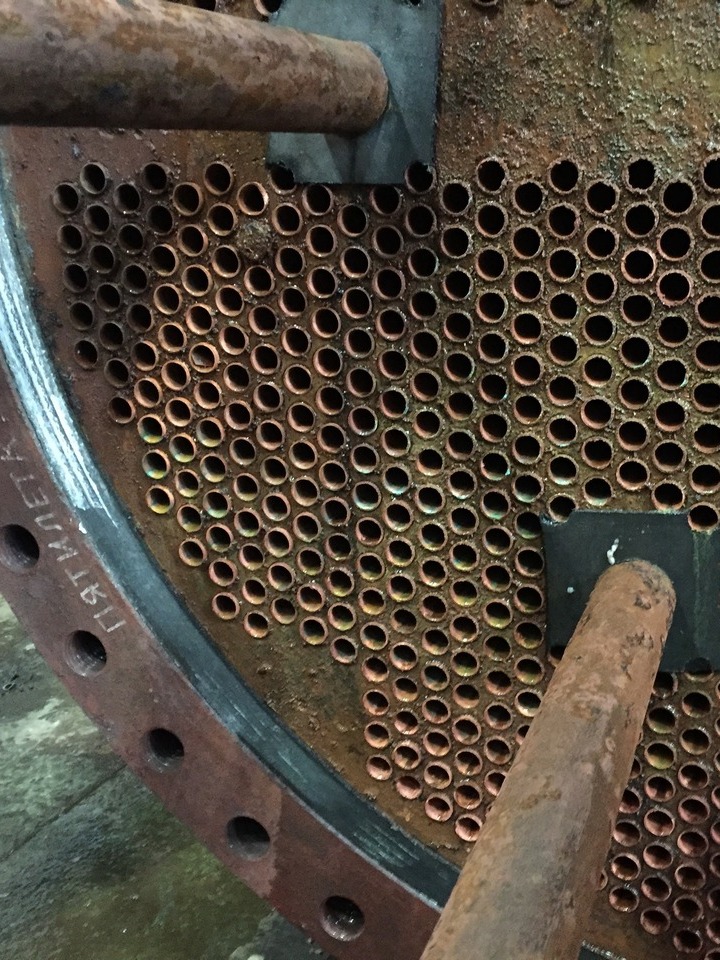

Types of deposits:

- Inorganic salts

- Heavy oil deposites, including petroleum coke

- Biofouling

- Rust

- Various non-reactive deposits

Types of equipment:

- Shell and tube heat exchangers, plate heat exchangers, etc.

- Capacitors

- Recycle gas coolers

- Water heaters

- Steam generating units

- Treatment facilities

- Evaporators

- Boilers

- Certain types of furnaces

- Pipes

- Tanks

- Other

Result of use:

BENEFITS OF THIS TYPE OF CHEMICAL TREATMENT:

- No disassembly required

- No need to dispose treating agents after cleaning (does not require additional treatment before draining into the sewer system)

- Single-stage process minimizes downtime of the equipment

- The integrity of the equipment and seals is guaranteed

- The most complete treatment, including removal of complex deposits in hard-to-reach places